Springs

Springs: Designed to Perform Manufactured to Lasts

Springs are one of the basic groups of machinery elements, together with fasteners, bearings, bushings etc. Springs are used in many mechanical systems that have a built-in relative movement between components.re one of the basic groups of machinery elements, together with fasteners, bearings, bushings etc. Springs are used in many mechanical systems that have a built-in relative movement between components.

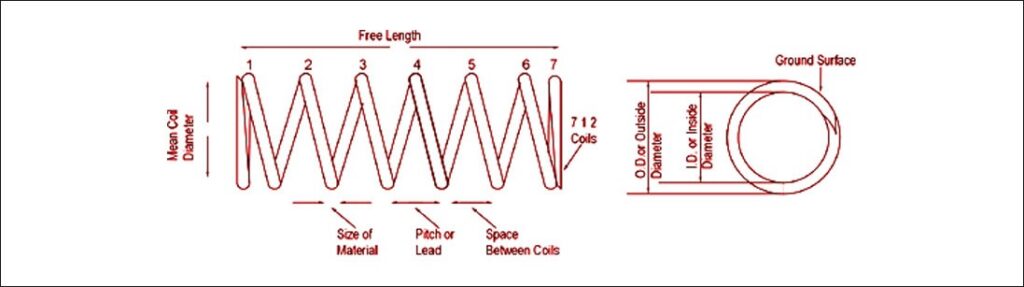

Compression Spring

SUSPENSION SPRINGS , CLUCTH SPRINGS , VALVE SPRINGS , FUEL INJECTION SPRINGS , FILTER HOLDDOWN SPRING , RELIEF VALVE SPRINGS , HYDRAULIC SPRINGS

open-coil helical springs wound or constructed to oppose compression along the axis of wind. Helical Compression is the most common metal spring configuration. These coil springs can work independently, though often assembled over a guide rod or fitted inside a hole.

Automotive Applications

- Suspension Spring

- Automotive shock absorbers

- Engine valve

- Clutch

- Filters

- Fuel injection

- Horns

Non-Automotive Applications

- Textiles

- Dispenser pumps

- Electrical & Machinery

- Medicals

- Railways

- Hospital Beds

- Wheelchairs & Pens

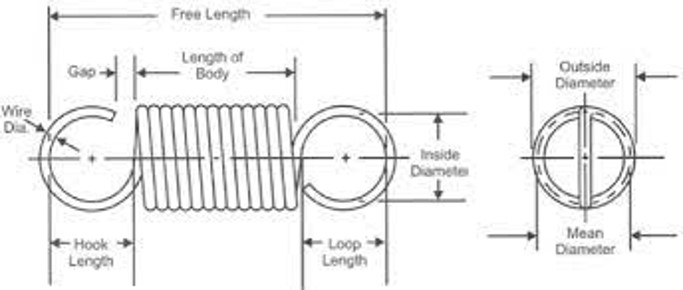

Extension Spring

BRAKE SPRINGS, PEDAL SPRINGS, TEXTILE SPRINGS

Extension springs, also known as a tension spring, are helical wound coils, wrapped tightly together to create tension. Extension springs usually have hooks, loops, or end coils that are pulled out and formed from each end of the body. The function of an extension spring is to provide extended force when the spring is pulled apart from its original length.

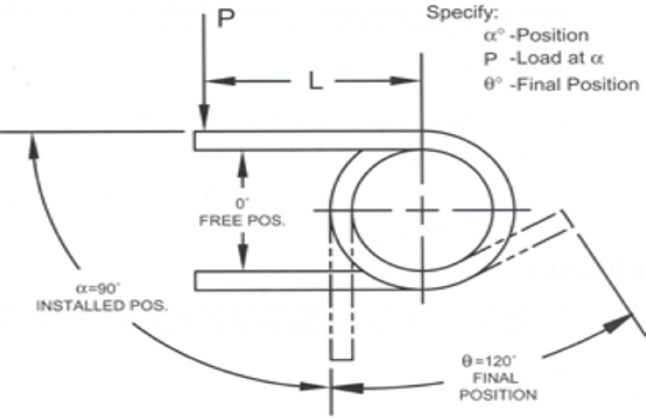

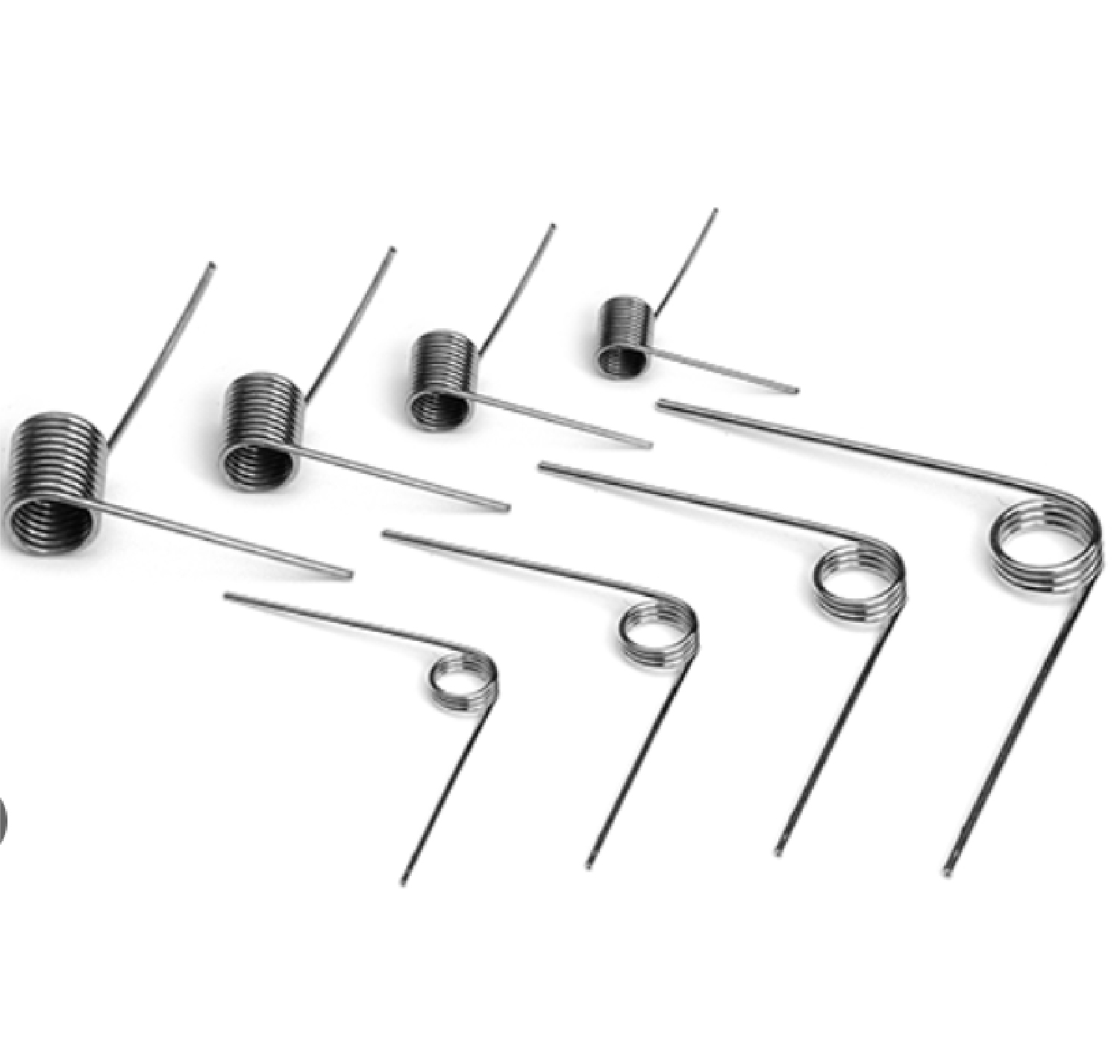

Torsion springs

KICK STARTERS , GEAR SHIFTERS , HANDLE SPRINGS

Type of mechanical spring that works by exerting torque or twisting force when it is twisted along its axis. The spring is made of wire that is wound in a spiral shape, with the ends of the wire attached to a stationary point on one end and a rotating point on the other end.

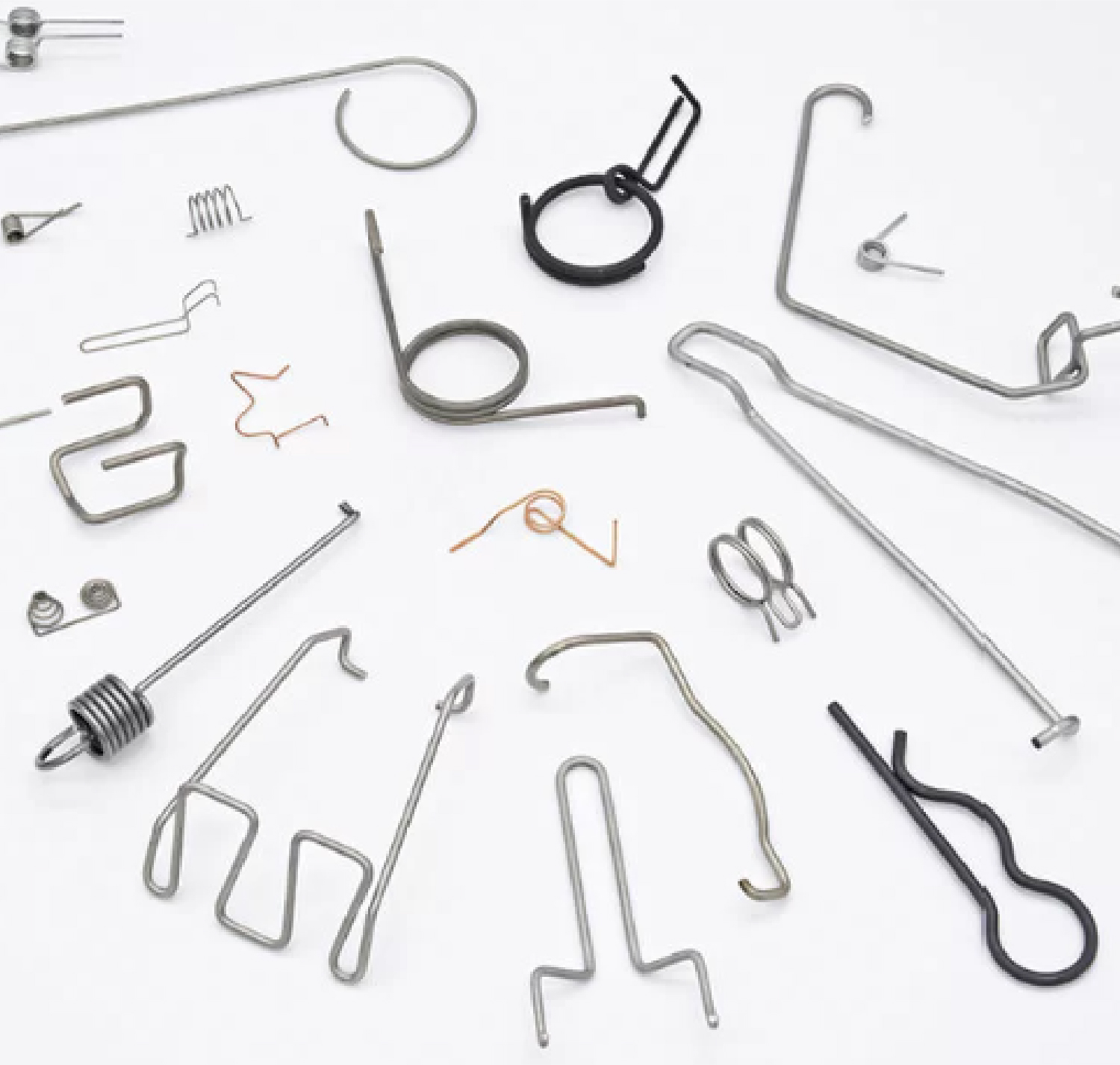

Wire forms

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed.

Applications

- Seat Frames

- Holders

- Cable holders for clutch & brake

- Locking arrangement,

- Roof lining,

- Door link,

- Bonnet hood rod

- Trunk lid mechanism

RAW MATERIALS

Common spring materials include stainless steel, alloy steels, carbon steels and some non-ferrous materials. IIS also produces spring from Exotic material like Inconel X-750, Inconel 718, Nimonic 90, Monel, Nimonic, Hastelloy, Beryllium copper etc.

Connect with SK Spring

At SK Spring , we are committed to provide good quality products to our customers, partners and stakeholders. Our experienced team is ever ready to support and serve. It’s time to embark on a fulfilling journey with SK Spring today!